Trussmatic, based in Helsinki, Finland, develops fully automated production systems for wooden roof trusses, transforming how the construction industry fabricates these critical structural components.

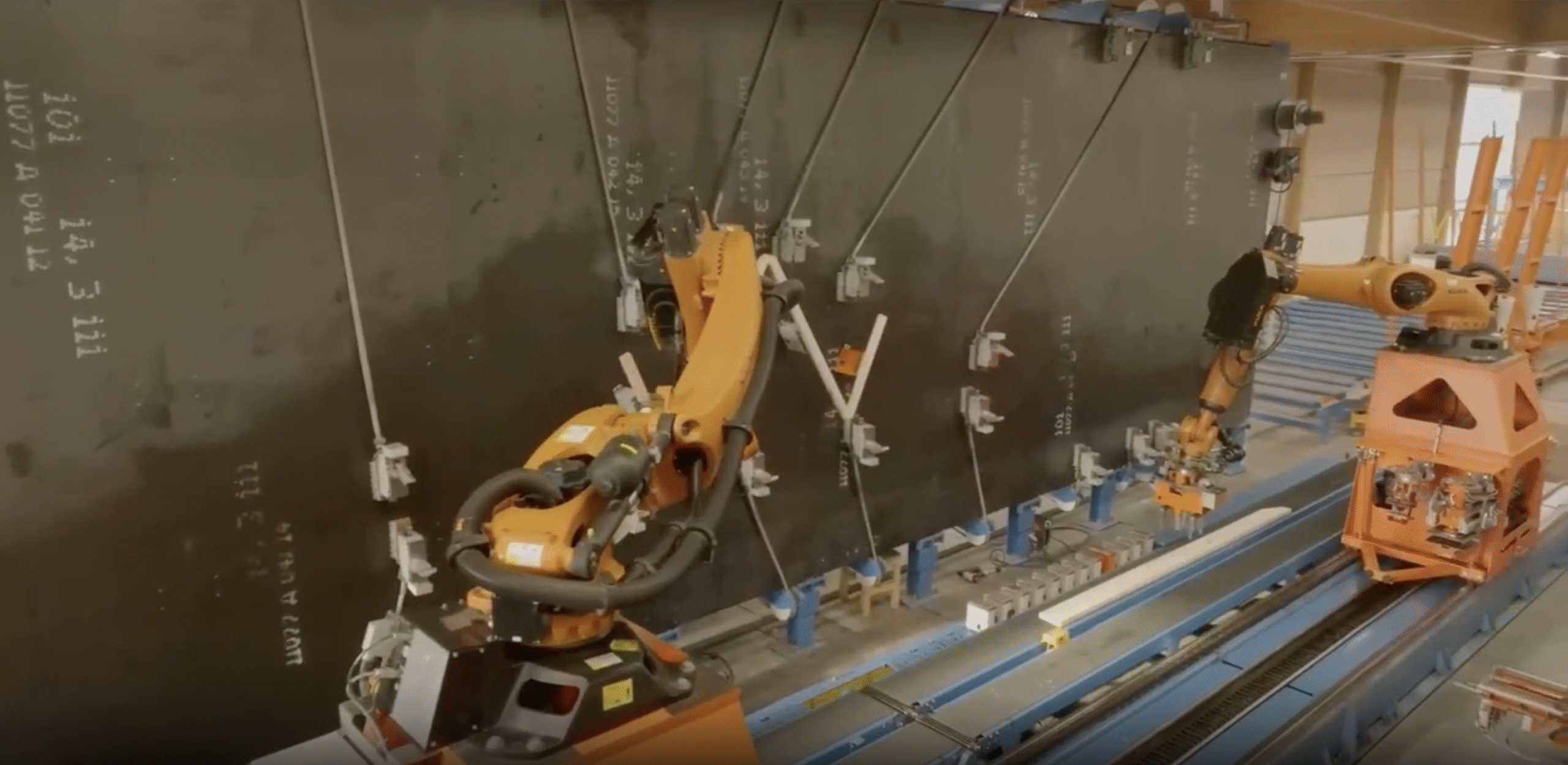

Their high-tech assembly lines reduce labor demands, improve precision, and significantly cut down production time and waste. Trussmatic’s solutions include robotic nailing, intelligent material handling, and real-time quality control—making the entire process hands-free from raw wood to finished truss.

These systems are ideal for high-volume production environments where consistency and efficiency are essential. The company supports both small truss manufacturers and large industrial players in modernizing operations and improving scalability.

By automating a traditionally manual and error-prone process, Trussmatic enhances safety, boosts profitability, and supports sustainable construction practices. As construction faces labor shortages and demand for faster build times, Trussmatic provides a forward-looking answer to industry-wide efficiency challenges.